DrainBeton®

High performance, pervious and sound-absorbing concrete

DrainBeton® is the only Italian patented pervious concrete for road applications.

DrainBeton® can be used as a single layer (either concretegrey or coloured) or covered with an open graded asphalt wearing course to create a dual pervious and soundabsorbing pavement.

The mix is casted cold, and as such there are no bitumen fumes emissions during paving operations and no risk to operators.

The workability of the mix allows it to also be laid using a slipform paver

Applications

Colors

Base colour

Natural grey.

Colouring with pigments

Yellow, ochre, orange, red, brown, green. Further tailor made pigments are available upon request.

Colouring using a mineralising solution

Can be tailor made: different colours available.

Drainbeton®

Videos

Projects

Sidewalks

Pederobba, in the province of Treviso

Sidewalks

Pederobba, in the province of Treviso

Parking for buses

Nago, province of Trento

Car park

Nago, province of Trento

Car park

Paving for sports fields

Marostica, province of Vicenza

Paving for sports fields

Province of Vicenza

Paving made for a cellar courtyard

Desenzano del Garda provincie of Brescia

Drainbeton® paving laid

Province of Vicenza

Pedestrian routes

Thiene, province of Vicenza

Parking lots: multifunctional areas

Realized using different colors of DrainBeton®

Cycle lane

Montebelluna, province of Treviso

Cycle lane

Montebelluna, province of Treviso

Cycle lane

“Monte Mesa” wind farm at Rivoli

Bike path and pedestrian paths

Riqualificazione dei Redevelopment of the Bosco Gardens in Thiene, in the province of Vicenza

Cycle lane

Pederobba, province of Treviso

Cycle lane

Zorlesco, province of Lodi

Cycle lane

Zorlesco, province of Lodi

Cycle lane

Cycle lane

Castell'Arquato, province of Piacenza

Cycle lane

Castell'Arquato, province of Piacenza

Cycle lane

Monteggiana

Road with low landscape impact

Low environmental impact roadway

Naviglio di Bereguardo, Parco del Ticino

Low environmental impact roadway

Grazzano Visconti, province of Piacenza

Low environmental impact roadway

Parco del Ticino

Low environmental impact roadway

Posina, area subject to environmental protection

Construction of a road for the passage of heavy vehicles

Quarry in Zanè, province of Vicenza

Secondary road

Province of Vicenza

Secondary road

Province of Vicenza

Advantages

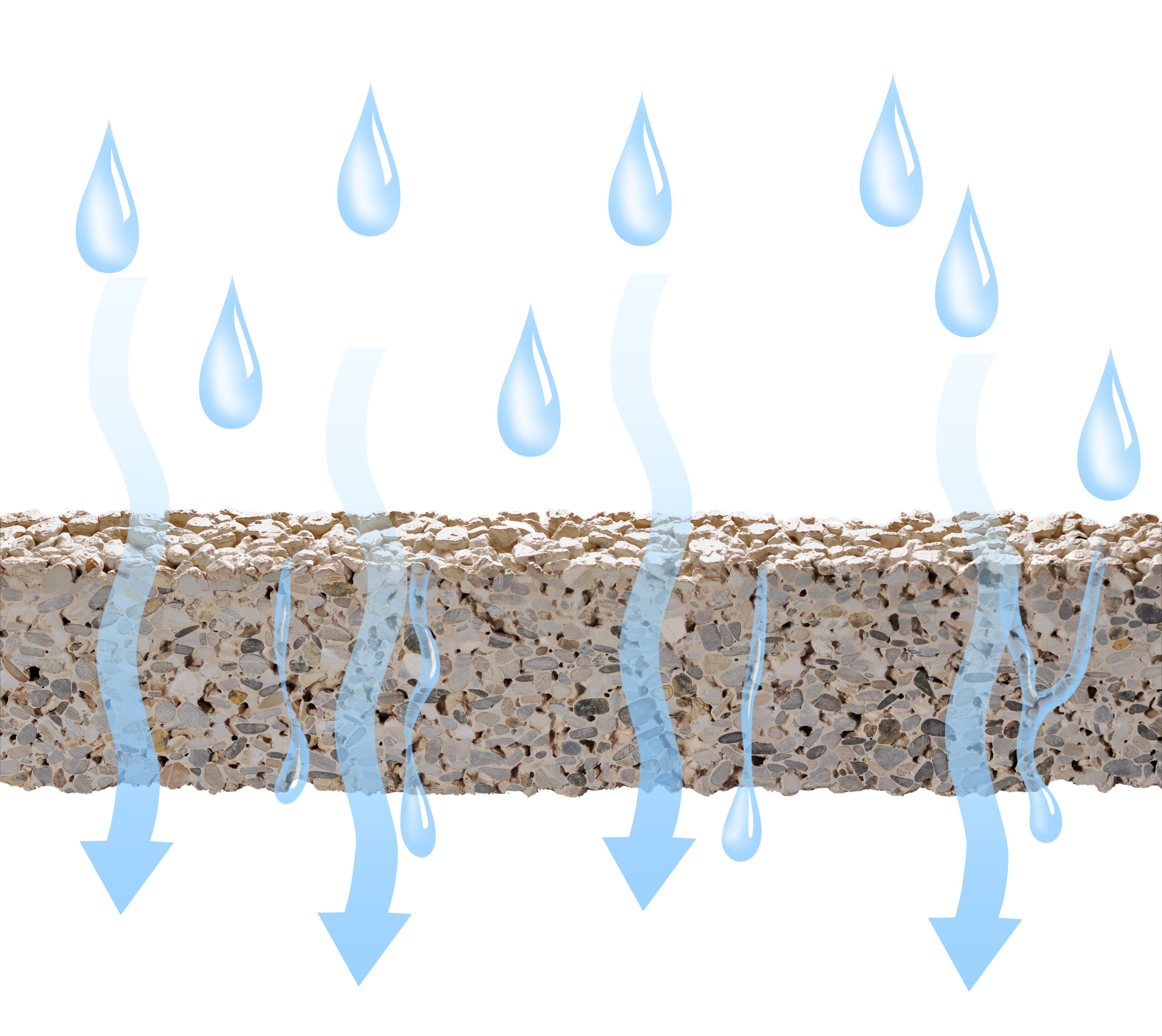

SURFACE DRAINAGE

Its high percentage of interconnected voids allows DrainBeton® to drain more than 30 l/sq.m per second, while still guaranteeing high load resistance values.

STRENGTH

In about three days after laying, DrainBeton® reaches compressive strength levels sufficient to open the road to vehicular traffic. The high levels of strength of DrainBeton® make it suitable also for road surfaces with high volumes of traffic.

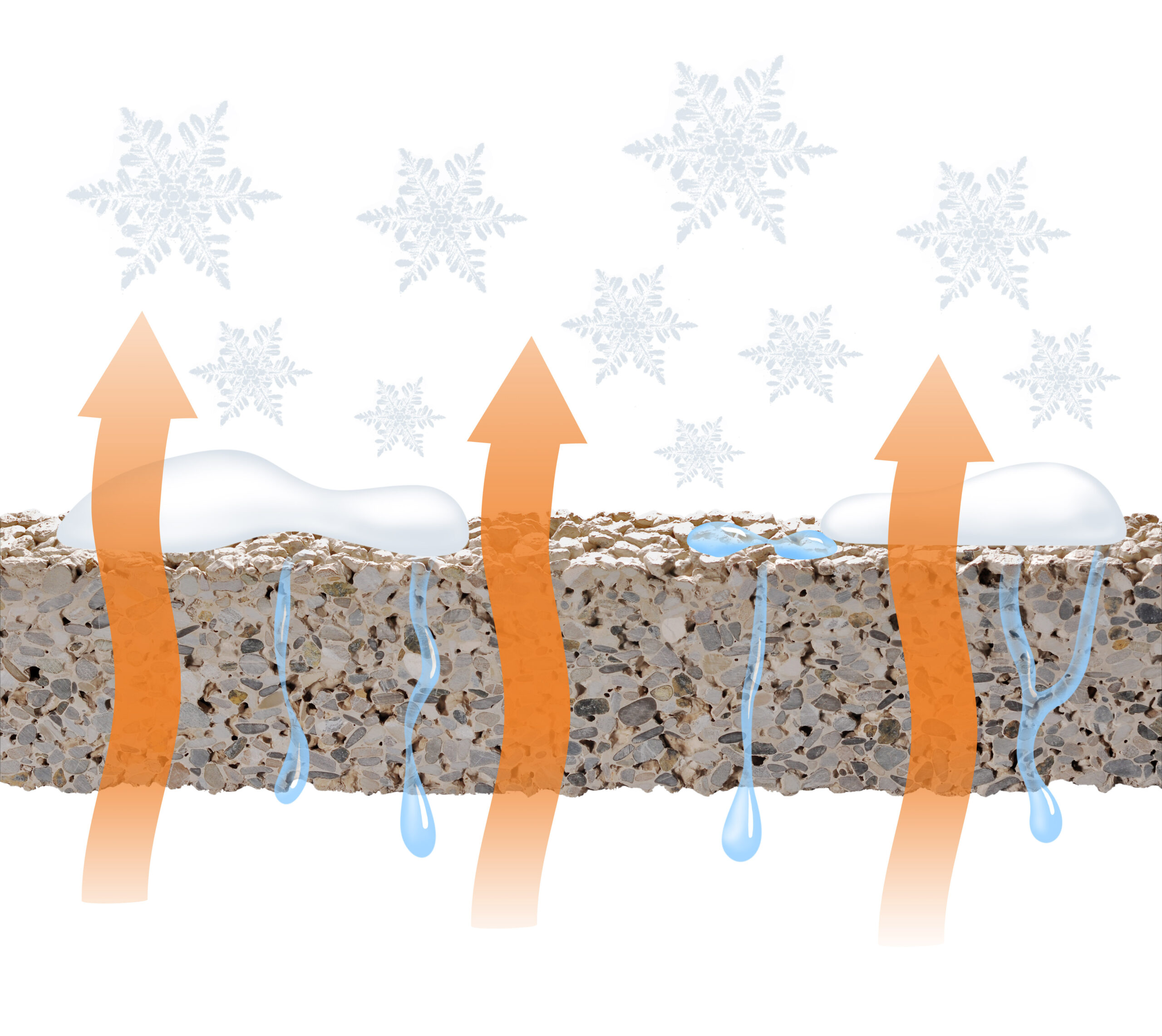

DE-ICING EFFECT

The open matrix of DrainBeton® allows air to circulate continuously, which accelerates the thawing process of snow and ice, and thus reduces the need for ploughing or clearing during winter. The presence of interconnected voids also allows any stagnating water to expand freely while it freezes.

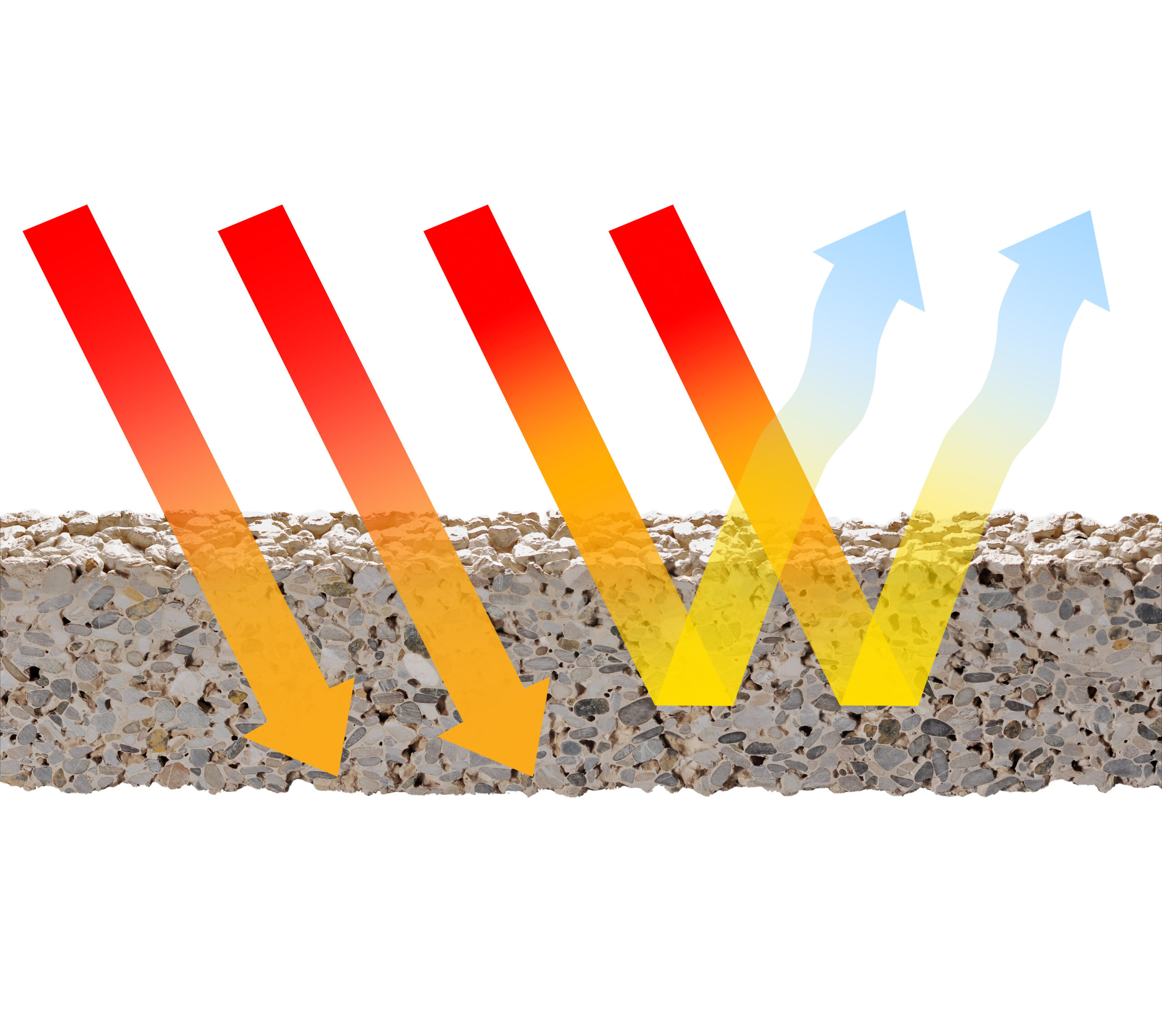

Isola calore

The light colour of the material and the high porosity of the mix lead to lower heat absorption compareds bituminous concrete, thus guaranteeing moderate temperatures for surfaces that are exposed to the sun. These characteristics of DrainBeton® enhance faster heat dissipation and a reduction of the heat island effect.

GROUNDWATER MITIGATION

Its excellent draining capacity make DrainBeton® particularly suitable for applications in protected areas, where rainwater must be allowed to pierce the soil. The material does not release polluting substances into the water as it drains through, and as its structure acts as a filter, there is less need for rainwater harvesting, thus reducing the harmful effects of potential contaminants.

RESISTANCE TO FIRE AND HYDROCARBONS

DrainBeton® is fire and hydrocarbon resistant. This allows it to be used in areas with a high risk of fire or fuel spills (e.g. car parks, petrol stations, fuel storage areas, etc.).

MINIMAL MAINTENANCE

The physical, mechanical and aesthetic characteristics of DrainBeton® remain unaltered over time, and it does not require any particular maintenance. In areas subjected to large quantities of detritus or dust, its draining capacity can be restored by cleaning it with high-pressure water or by using a street sweeper.

ENVIRONMENT-FRIENDLY COLD LAYING

Laying DrainBeton® is an environment-friendly operation as it is carried out “cold”, so with no emission of fumes, no risk to the safety of the operators, and a significant saving in energy requirements.

Methods of laying

DrainBeton® can meet construction site requirements, reducing laying times and costs.

The mix was expressly designed to be laid by a slipform paver or manually using lightweight tools.

Laid cold

The cement is laid cold, so there are no emission of fumes and no risk to the safety of the operators.

Laying

The concrete can be laid at room temperatures much lower than those recommended for bituminous mixes.

Low hydraulic shrinkage

The low hydraulic shrinkage of the material means no contraction joints, except for possible technical reasons linked to thickness of the geometric shape of the paving.

The sub grade

It requires a subgrade with the same regularity and load-bearing characteristics as normally needed for road construction.

DrainBeton®

Laying using slipform paver

The workability of the concrete enables it to be laid using the same methods and machinery as normally used for road paving. Laying using a slipform paver is in all points similar to laying asphalt, but at room temperature, and with no fume emissions into the atmosphere. DrainBeton® is compacted directly by the paver’s screed and additional rolling is not required. This makes laying faster, and also gives full control over the thickness and smoothness of the surface.

DrainBeton®

Laying using other methods

DrainBeton® can be laid manually using lightweight handheld tools (vibration smoothing, roller screed, etc.).

Dual permeable sound-absorbing road pavement

DrainBeton® can therefore replace the base course and binder (which are normally impermeable), giving the package not only both permeability and soundabsorption qualities, but also lower deformability and greater load resistance, thus prolonging the surface life of the pavement.

Lower defomability and greater load resistance.

The advantages of the double layer configuration

Thanks to the asphalt wearing course, the permeable road pavement looks “normal”, and as such is both well-received by both Public Authorities and road users.

Also thanks to the asphalt wearing course, surface grip, smoothness and compatibility with road markings are guaranteed.

The presence of two highly porous layers gives the paving a high self-draining capacity as well as sound absorbing properties at different sound frequency levels.

Thanks to the load-bearing capacity and fatigue strength of the concrete, the paving has a long service life with minimum maintenance, and this affecting principally the asphalt wearing course.

The double permeable layer with its selfcleaning action reduces blockages in the interconnecting voids to a minimum, thus prolonging the self-draining properties of the material over time.

The construction and maintenance costs are lower than those of a traditional road package.

Download technical data sheet

Download brochure

Browse the brochure

Applications

Applications Colors

Colors Videos

Videos Projects

Projects Advantages

Advantages Laying methods

Laying methods